Metering machines made by Hennecke

Mixing and metering without any quality compromise with machine technology for every conceivable and inconceivable application: for more than 50 years, metering machines from Hennecke have been synonymous with top quality polyurethane processing and have been the centrepiece of countless processing plants. The Hennecke lineup comprises modular configurable systems for small to large outputs with first-class metering pumps, a great choice of state-of-the-art mixheads and intelligent automation.

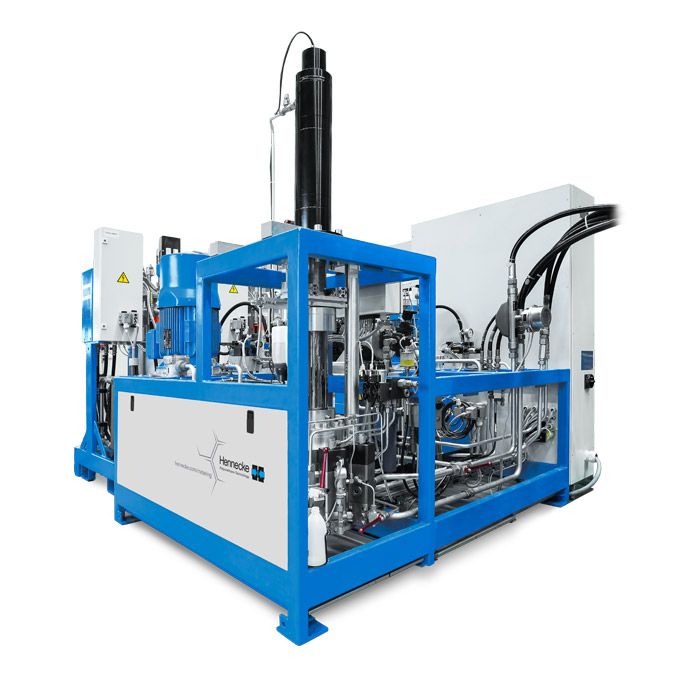

High-pressure metering machines

For the production of rigid and flexible foams as well as integral skin foams

More than half a century ago, the HK type series heralded a new era – high-pressure polyurethane processing. Today, high-pressure metering machines form the basis when it comes to processing a whole variety of PU applications. Depending on the plant configuration and the mixhead used, modern metering machines allow all kinds of rigid and flexible foams as well as integral skin foams to be produced. The consistently modular construction offers processors more flexibility, also in the long term, if, for example, they later wish to expand production or combine with production plants.

All high-pressure metering machines at a glance

#nextgenstore

The world's first configuration platform for metering machines.

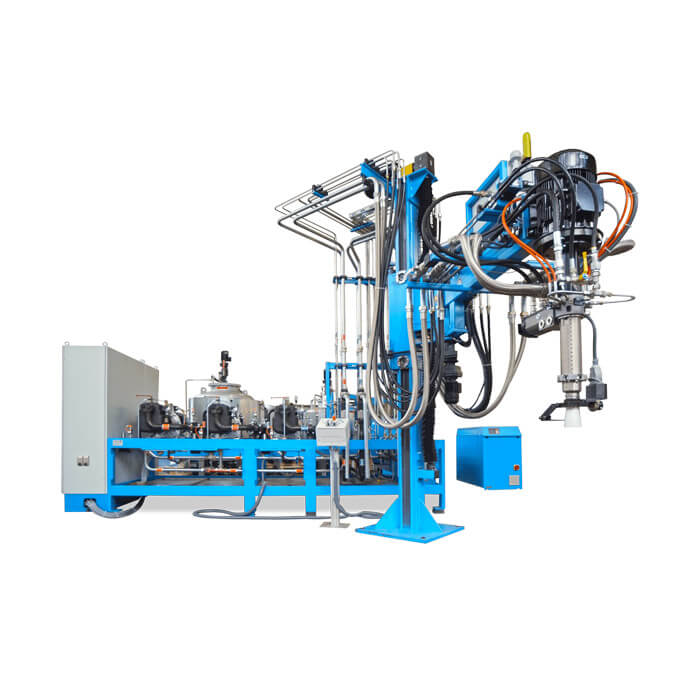

Low-pressure metering machines

For processing casting sytems or highly viscous components

When it comes to processing raw material systems used in the low-pressure range Hennecke offers you – just as in high-pressure metering – state-of-the-art systems technology as the basis for perfect, high-quality end products. Hennecke also has decades of experience in low-pressure metering systems. For example, in the processing of casting systems or raw materials with high viscosity for making elastomer components or thermoformable foam products. Users also benefit here of course from the advantages offered by modular configurable systems which are flexible and can be adapted to any application.

All low-pressure metering machines at a glance

Elastomer casting machines

For high or low-pressure processing of casting systems or highly viscous components

When it comes to processing casting systems or highly viscous components, Hennecke provides state-of-the-art systems technology as a basis for flawless, high-quality end products. The parts produced with these systems can be divided into solid and cellular elastomer products. Compact polyurethane elastomers are suitable for a variety of moulded parts, high-quality wheels and rollers and also semi-finished products for mechanical processing. These parts are used when maximum abrasion resistance as well as mechanical and physical strength are important. In contrast, due to their excellent material properties, polyurethane elastomers with a micro-cellular structure are used when considerably greater deformation and lower compression hardness are required compared to the solid elastomers. Users also benefit here of course from the advantages offered by modular configurable systems which are flexible and can be adapted to any application.