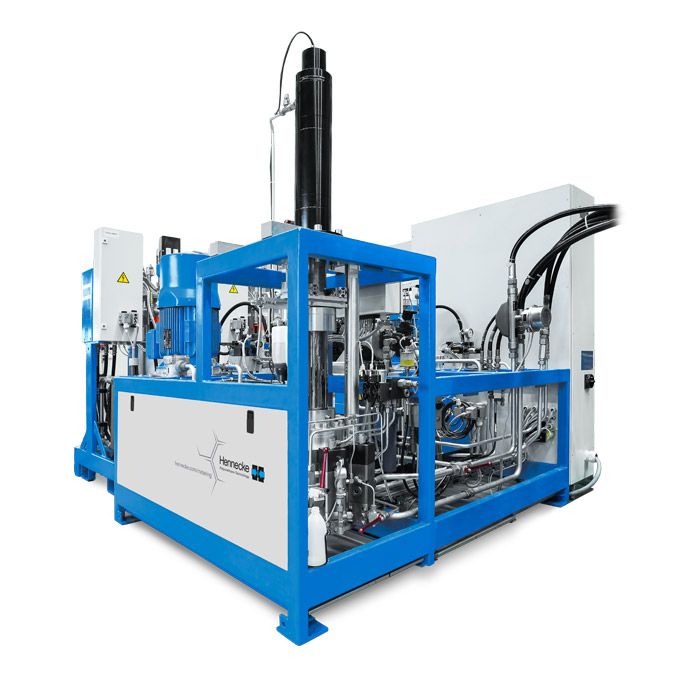

ECOPLUS MK2

NEW The ECOPLUS MK2 is the first model from Hennecke's new 'NEXT-GEN metering machines' and has been completely reworked compared to the previous generation. The cost-efficient starter model provides an easy introduction to Hennecke's quality high-pressure metering for largely manual polyurethane production, without compromising on mixing quality, raw material efficiency and digitalization. As well as making a number of noticeable optimizations to the machine layout, development focused on factors such as sustainability, resource utilization, energy consumption and data integration. All in all, the ECOPLUS MK2 offers higher performance at a lower purchase price. Nevertheless, the focus is on the highest quality in all crucial elements. The mixhead, metering line and automation are all new developments with many detail improvements.

- The groundbreaking HX metering pump is significantly more pressure-resistant, quieter and more energy-efficient. Integrated sensor technology provides the user with extensive information as well as support in achieving optimum system availability.

- The mixhead is the MT-E model in various sizes, offering the perfect balance of functional operability and the high-performance design features of the MT-A series.

- Of course, the latest Hennecke injector generation is also included with the FIXJET or FLEXJET SL models – another highlight in this price segment.

- The control system features the latest SIMATIC platform components. The high-resolution, premium HMI with powerful CPU is home to a completely new and intuitive visualization system. The FOAMATIC provides the operator with maximum performance and fast access for a wide range of applications.

Thanks to the standard use of Hennecke's Blue Intelligence technology, the ECOPLUS MK2 is significantly more energy-efficient, depending on the production scenario. At Hennecke, Blue Intelligence encompasses all the measures serving to enhance the sustainability of production systems. In the case of the ECOPLUS MK2, this includes, for example, energy use when no shot is called, the automatically determined pump lead time, and efficient pumps that are more raw material-efficient due to improved temperature management. Based on the individual production scenario, savings of up to 50% can be made.

#nextgenstore

The world's first configuration platform for metering machines.

Click here for accompanying documents in the PDF format

You will need Adobe® Reader® that you can download here for free.