Hennecke, the global leader in polyurethane processing technologies, will be presenting its solutions for slabstock foam production at Foam Expo Europe in Stuttgart from December 3 to 5. At stand no. 617, trade visitors can expect an insight into innovative technologies and proven systems. Hennecke's experts will be available on site for personal meetings to discuss individual questions and specific requirements.

Focus on technology: JFLEX evo and FOAMWARE SLABSTOCK

Hennecke invites visitors to the trade fair to find out about the latest developments and functions in the field of system technology and peripherals. The focus will be on two highlights:

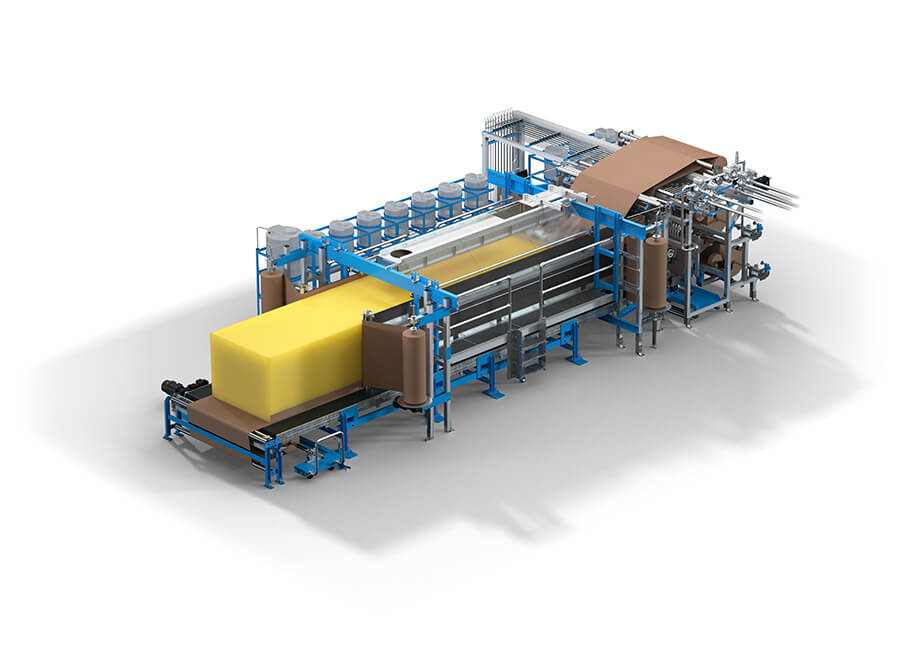

JFLEX evo: The revolutionary plant for slabstock foam production combines compact design and maximum process reliability. The JFLEX evo builds upon the concept of the tried and tested JFLEX and optimizes it in key areas: continuous adjustment of foam widths, improved rise-plate geometry, a Page 2 of 3 standard FLAT-TOP system and integrated walkways on both sides along the foaming tunnel.

FOAMWARE SLABSTOCK: The advanced control software for slabstock lines impresses with its intuitive operation and comprehensive process monitoring. Thanks to the flexible plug-in concept, specific production requirements such as optimization and predictive maintenance can be easily integrated. The third-party interface enables the highest possible degree of connectivity to higher-level ERP systems. A self-sufficient, additional industrial PC ensures maximum IT security. The FOAMWARE SLABSTOCK is also available as a retrofit solution, allowing existing systems to be comprehensively upgraded.

Hennecke will also be providing information in Stuttgart about the latest developments in the tried-and-tested QFM and MULTIFLEX plants. These systems for continuous slabstock foam production are characterized by precision, excellent foam quality and the best possible raw material yield.

Retrofit and service solutions for maximum efficiency

In addition to innovative plant solutions, Hennecke will be focusing on retrofitting and service at Foam Expo Europe. With the 360°RETROFIT portfolio, the company supports its customers in bringing their existing production plants up to the latest state of the art through targeted upgrades. This enables a significant increase in efficiency and extends the service life of the machines. Hennecke also provides information about new service contracts, which include continuous software updates and access to the latest plug-ins and functionalities. They guarantee users maximum plant availability and carefree operation at all times.

Exchange and expertise at Foam Expo

“Foam Expo is an ideal platform to demonstrate our expertise in polyurethane processing and to intensify the exchange with our customers,” explains Joachim Berthold, Senior Director Sales Technical Insulation Lines, Molded Foam & Slabstock. “Our extensive range of services in particular underlines our commitment to sustainably optimizing our customers' processes.”