At PU Tech India 2025, which is taking place from April 9-11, 2025 at the India Expo Centre in Greater Noida near New Delhi, Hennecke is presenting its latest technologies for polyurethane processing in hall N1, stand C01. The focus will be on continuous slabstock machines, in particular the MULTIFLEX series, as well as the innovative control software FOAMWARE. In addition, Hennecke is proud of its growing presence in the molded foam field on the Indian market.

MULTIFLEX: Efficient production of high-quality slabstock foams

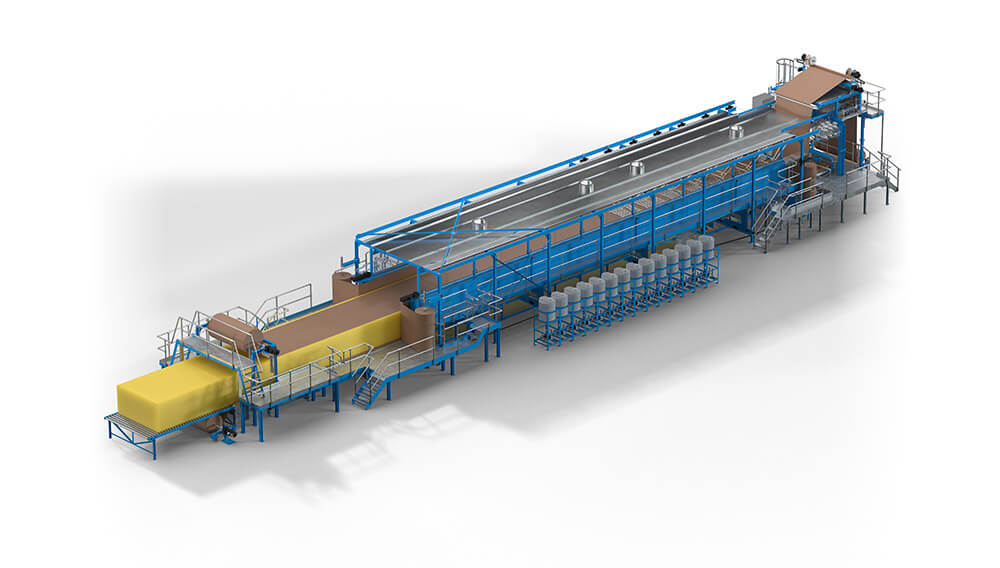

Hennecke has been active in India in the field of continuous slabstock machines for nearly two decades. More and more Indian producers are relying on Hennecke technology to meet the increasing requirements for a sustainable and efficient production, as well as to meet international quality standards. With the MULTIFLEX, which will be put into operation at Shakti Foams Pvt Ltd in 2025, the company is celebrating its 25th continuous slabstock machine on the subcontinent. The MULTIFLEX series impresses with a high production flexibility, first-class foam quality, and a particularly efficient use of raw materials. The latest high-pressure technology makes significant material savings possible, while the innovative LIQUID-LAYDOWN system combined with the FLAT-TOP system ensures a particularly homogeneous foam structure and high raw material efficiency. Moreover, Hennecke will provide information at the trade fair about the QFM and JFLEX slabstock series. The latter recently celebrated its debut as JFLEX evo and has been impressing customers with decisive improvements: continuous width adjustment, optimized riser plate geometry, FLAT-TOP system and walkways on both sides of the foam tunnel.

The latest control software for maximum efficiency

In addition to innovative system technologies, with FOAMWARE Hennecke is presenting its innovative solution for control systems and the optimization of production processes. The software allows for precise process control, comprehensive data acquisition, and visualization through features such as Flow Chart, Process Chart and Calibration Manager. This leads to a significant increase in efficiency and improvement in quality, for example by detecting dosing deviations early on and preventing production standstills. FOAMWARE is not just the standard solution for new systems, but can also be retrofitted for existing slabstock machines to bring older systems up to date and improve their IT security. "The FOAMWARE is a milestone: It allows us to bring old systems into the digital age and take them to a whole new level," explains Christian Becker, Director Sales South East Asia / India at Hennecke Asia Pte Ltd. FOAMWARE is a crucial factor on the path to digitization and, in addition to intuitive user guidance, offers extensive opportunities for process analysis, production optimization and predictive maintenance by archiving and analyzing calibration data.

Expansion in the field of molded foams

Hennecke is also increasing its commitment in the molded foam sector. In the year 2025, two fully-equipped WKH foam molding plants will be installed in India. These systems allow for the fully automated manufacture of molded foam parts such as seats, backrests and headrests, and are specifically designed for demanding applications in the automotive industry where damping, insulation and pleasant touch and appearance are key. Hennecke is setting new standards here in a market segment that was previously dominated by local manufacturers.

Individual consultation at PU Tech India 2025

Hennecke will be represented by a team of experienced experts at the trade fair and will provide information about the latest developments in molding and slabstock foam production. Visitors are invited to seek advice regarding technologies, retrofit solutions and individual applications at the stand.