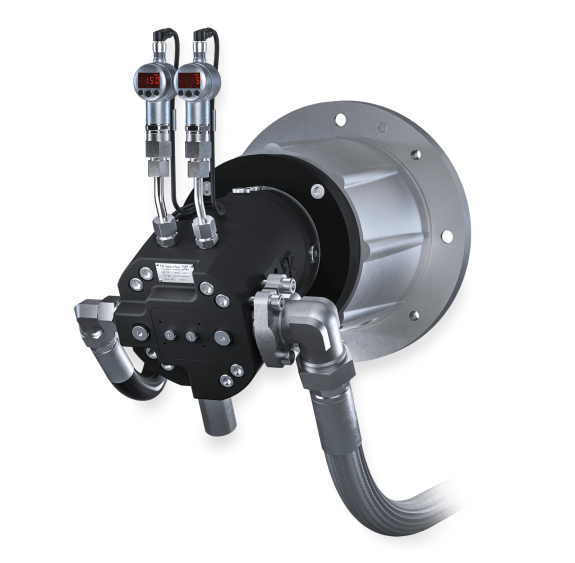

Series HX

With the pump HX series, Hennecke presents the first axial piston pump that has been developed exclusively for polyurethane applications. Development focused on creating a precise, highly efficient and future-fit metering line that offers Hennecke customers real value when processing polyurethane. The HX series is a completely new pump generation and is manufactured exclusively at our Sankt Augustin site.

Optimized Design

The HX series offers a significantly optimized pump housing, enabling maximum bearing flushing thanks to a newly developed bearing seat. This ensures efficient heat dissipation and prevents a rise in the reactive media temperature. This highly effective self-cooling even works at high ambient temperatures and offers a significant advantage compared to other pumps on the market. The selection of materials and their surface protection were specially designed for use in polyurethane foaming systems.

The pump housing has a compressive strength of up to 16 bar. This ensures more efficient heat dissipation from the high-pressure pump even in the event of high pre-pressures.

The pump design improves suction. This is a particularly noticeable advantage when working with high-viscosity components, so that the HX pump can be supplied with lower pre-pressures depending on the area of use. It may mean that pre-pumps are not required.

Predictive Maintenance

Furthermore, the HX series is equipped with a sensor, which makes it possible to integrate the pressure and temperature monitoring directly into the pump housing. The housing is also prepared for a retrofittable distance sensor. This monitors the pump bearings, sends pre-set wear limits and makes predictive maintenance of the pump system possible.

More Sustainability

The new HX scores highly in terms of sustainability: The increase in efficiency leads to an optimized energy balance in the entire system. Thanks to its reduced volume, it also greatly increases raw material savings during flushing operations in comparison to conventional pumps. The HX impresses thanks to reduced noise emissions in operation and facilitates easy processing of modern raw material systems based on bio-based or recycled polyol.

The Advantages of the HX Pump at a Glance:

- Efficient self-cooling: The optimized design of the pump housing with maximum bearing flushing makes efficient heat dissipation possible and prevents unwanted reactions from reactive media.

- High compressive strength of the housing: The maximum pre-pressure is 16 bar in an open circuit.

- Saves raw material: The reduced chamber volumes save a significant amount of valuable raw materials during the flushing process.

- Predictive Maintenance: Integrated sensor monitors the pump and lays the foundation for predictive maintenance measures.

- Optimized shelf life: The HX series offers improved protection against chemical degradation by abrasive or corrosive polyol materials.

- Modern raw materials: New raw material systems such as bio-based polyol or recycled polyols can also be easily processed.

- Maintenance-friendly design: With significantly fewer components than a typical pump and the integrated safety valve, the HX series is less susceptible to errors and is easier to assemble and maintain.

- Sustainability: The HX series has an optimized energy balance and lower noise emissions.

- Versatile: The HX series is impressive not only in use with single metering machines, but can also be used effectively in several systems.

360°RETROFIT

Take your system to the next level with the HX series

Originally developed for the NEXT GEN single metering machines, the HX series is now also approved as a RETROFIT for existing systems. As the pumps are used in standard metering machines and manufactured by us at Hennecke, shipping availability is always guaranteed. The exchange is usually simple and possible at short notice.

Contact the Hennecke 360°SERVICE for more information on how you can make use of the advantages of the HX series.

Technical data

- Sizes: HX06, HX12, HX28

- Max. permitted pre-pressure: 16 bar

- Viscosity range: up to 8000 mPas

- Volume: 200 cm³

- Flow capacity: 25 cm³/s – 770 cm³/s

- Speed range: 300-1800 U/min

- Noise level: 75 dB