At interzum 2025, which will take place in Cologne from May 20 to 23, Hennecke will show how sustainable production technologies and intelligent retrofit solutions are changing the furniture supply industry. interzum is the world's leading trade fair for furniture production and interior design and showcases technological advances and sustainable material concepts. In line with this year's main theme "Rethinking Resources: Circular and Biobased Solutions", Hennecke will be presenting innovative concepts for conserving resources, using energy more efficiently and making existing plant technology fit for the future at stand D049 in hall 9.1.

Focus on sustainability

Sustainability is not a trend at Hennecke, but is deeply rooted in the company's identity. For decades, Hennecke has been pursuing the goal of making production processes more efficient, more stable and more resource-friendly - technologically leading and practical at the same time. At interzum 2025, this aspiration will be particularly evident in the slabstock product area, where the company will be showcasing concrete solutions for sustainable PU processing. "Our customers are under increasing pressure to produce efficiently and sustainably. With our innovative technologies and retrofit solutions, we enable them to achieve exactly that - without compromising on quality or cost-effectiveness," explains Joachim Berthold, Senior Director Sales Slabstock Lines. Three current developments exemplify this approach:

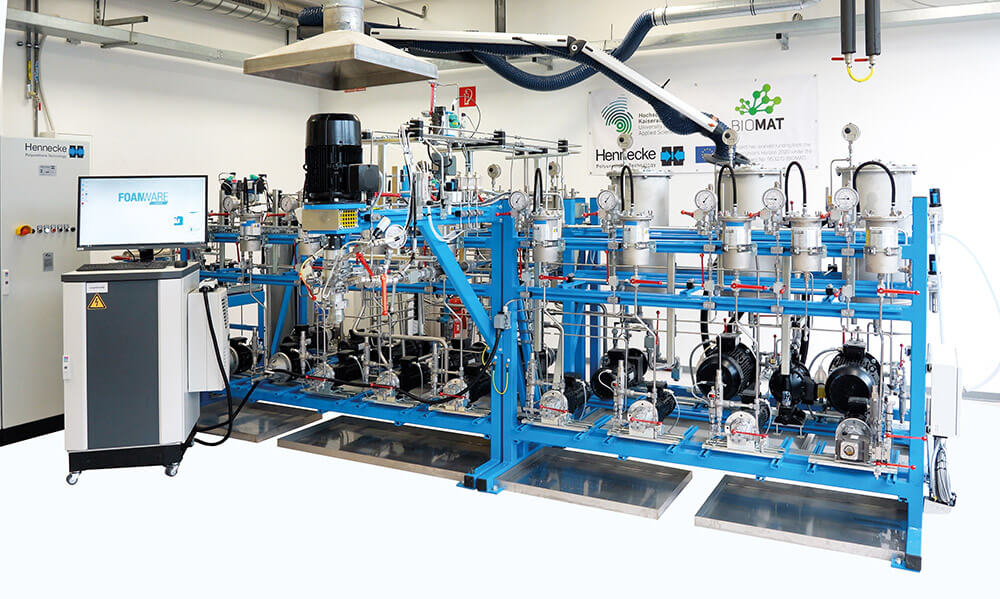

- Increased use of biopolyols: Hennecke is supporting the Kaiserslautern University of Applied Sciences by cooperating in the development of pioneering alternatives to classic PU raw materials as part of the international EU project BIOMAT. The polyol used comes from bio-based or recycling-based sources and enables high-quality foams with reduced environmental impact. Hennecke‘s LABFOAM pilot plant is being used for the numerous practical tests.

- Sustainable flame protection with expandable graphite: safety, environmental compatibility and performance can also be achieved entirely without halogenated substances. The use of the environmentally friendly filler expandable graphite requires adapted metering technology, which Hennecke offers as an option for its slabstock systems.

- Environmentally friendly NOVAFLEX® technology: By using CO2 as an alternative blowing agent, NOVAFLEX® replaces conventional chemicals such as CFCs or methylene chloride. The result is an efficient foaming process with an improved ecological footprint and a unique soft-touch foam surface.

Retrofit solutions for existing systems

The company also focuses on efficient and production-oriented retrofit solutions that can be used to modernize existing systems and significantly increase their efficiency. In view of the extremely long service life of Hennecke plants, this is an important contribution to increasing efficiency and process stability. Even plants that are decades old can be upgraded in many cases and raised to a new level. The innovative retrofit solutions include:

- Auto-Flat system: Automates the height and side adjustment of the familiar rectangular device (Flat-Top System) and ensures consistently uniformly shaped foam blocks. This significantly reduces waste and thus saves raw materials.

- Rise Profile Management: actively records and regulates the rise profile of the foam with the help of sensors along the foaming section. Recipe fluctuations can thus be detected at an early stage and corrective measures can be initiated.

- FOAMWARE plant control system: combines intuitive operation with comprehensive monitoring and ensures maximum transparency and efficient control of continuous slabstock plants. At the trade fair, the Hennecke experts will be presenting numerous innovations of the current "FOAMWARE 2025" software generation.

As a special service, Hennecke will be offering two presentations each day during the trade fair from May 20 to 22 on the topic of innovative retrofits in the field of slabstock production. PUR professionals will provide practical insights into the possibilities of making existing plants more efficient and sustainable. Interested parties can register for participation directly at the Hennecke stand.

A team of experts from Hennecke will be on site throughout the trade fair and will be available for individual discussions with users, customers and interested parties. The focus will be on customized retrofit measures, sustainable solutions and concrete ways to increase efficiency in polyurethane processing.